In a changing world it was clear that, now and in the future more people wanted to hold on to their independence and remain in their homes, and that people with disabilities wanted to bathe safely.

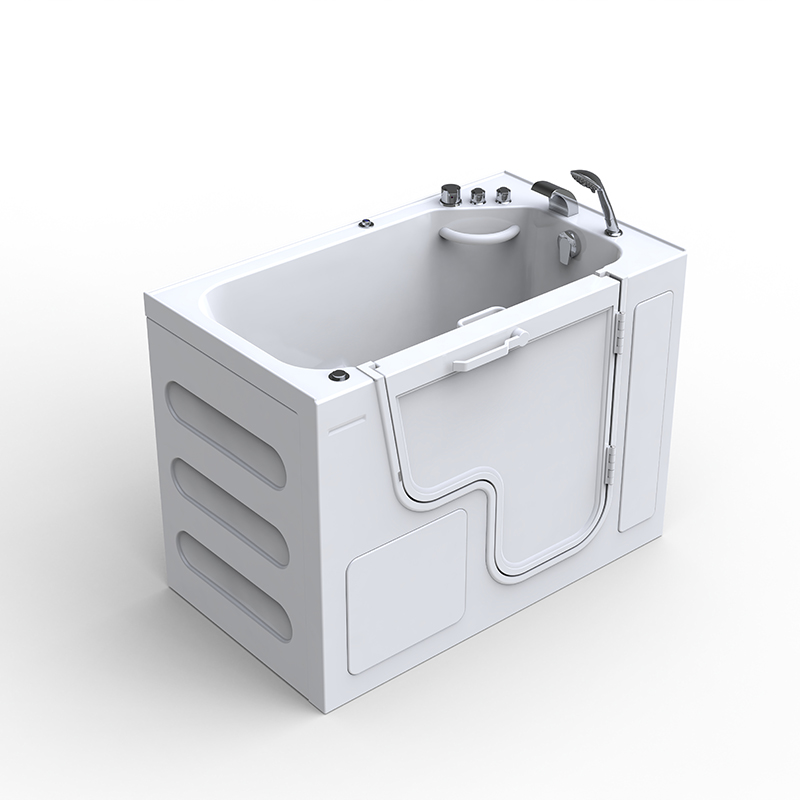

We launched with our innovative outswing door, before this almost all walk in bath companies produced inswing walk in baths as this technology was easy to produce but made it difficult for the customer to enter and exit.

Also, upon launching it was important to get the design right, for too long the designs had looked institutionalized and out of date, with modern CAD programs and state of the art manufacturing techniques we were able to bring the designs in to the 21st century, and that would look right in any modern bathroom setting.

We introduced new technologies such as water jets, air jets, re-heaters, chromatherapy, ozone cleaning, heated back and seat, aromatherapy and the standout microbubbles technology which allowed our customer base to keep their skin in top condition which is important for the elderly and the less mobile.

Our Philosophy is simple, we exist to keep pushing the boundaries of what is possible with Walk in Baths, exploring this further, what does it mean?

Engineering using the latest in CAD design and engineering CNC technology adopted throughout all processes of the factory from the moment we have the inspiration to a new bath until it rolls off the factory line.

Quality control, arguably the most important process in the factory, as the factory is divided into substations each bath has its own electronic file which is virtually passed from substation to substation, with the substation’s supervisor signing off on the bath as it leaves a substation. Each serial number is unique and individual to every bath. Water testing is the most important part of the QC process and on our water test line, we test each bath for 12 hours to ensure perfect reliability.