Inspection & Testing Overview

To ensure the highest standards of safety, quality, and user satisfaction, every walk-in bathtub undergoes a comprehensive inspection and testing process before leaving our facility. The key evaluation areas include:

1. Structural Integrity

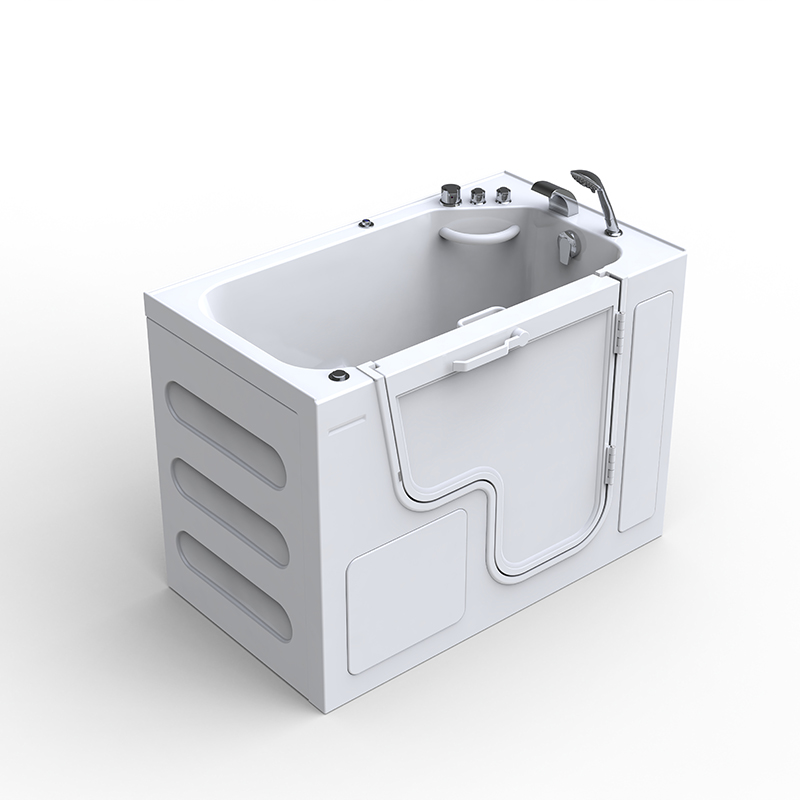

Surface Inspection: Examine the bathtub’s surface for any cracks, scratches, or signs of deformation.

Joint Integrity: Ensure all joints are tightly sealed with no leaks or looseness.

Support Frame Check: Verify that the structural support is stable, corrosion-free, and securely fastened.

2. Waterproof Performance

Leakage Test: Fill the bathtub to check for any water seepage from the tub body or surrounding areas.

Seal Condition: Inspect all seals around doors and joints to ensure they are intact, undamaged, and free from aging.

3. Doors and Locking Mechanism

Door Operation: Confirm that doors open and close smoothly without resistance or abnormal noise.

Lock Security: Test door locks for firmness and reliability, ensuring they prevent accidental opening.

4. Drainage System

Drainage Efficiency: Evaluate the speed and smoothness of water drainage, ensuring there is no blockage.

Drain Valve Function: Ensure the valve operates properly and seals completely to prevent leaks.

5. Safety Features

Anti-Slip Surface: Inspect the bottom of the tub and surrounding area for effective anti-slip treatment.

Grab Bar Strength: Confirm that all grab bars are securely mounted and capable of supporting user weight safely.

6. Electrical Safety (for models with electrical components)

Functional Test: Check heating, massage, and other electronic features for proper operation and safety.

Grounding & Insulation: Ensure all electrical components are correctly grounded and well insulated to meet safety standards.

7. Hygiene and Cleanliness

Clean Appearance: Confirm the tub interior and surrounding areas are clean and free from stains, mold, or debris.

Sanitization: Verify that all surfaces have been properly disinfected in accordance with hygiene regulations.

8. User Experience

Control Accessibility: Test whether the control panel or buttons are responsive and user-friendly.

Space & Comfort: Evaluate the interior space for adequate room and ergonomic comfort during use.

9. Operational Noise

Noise Level Test: Monitor for abnormal sounds during the operation of pumps, motors, and other mechanical parts, ensuring quiet performance.