The Strength Behind Every Walk-In Bath: Why Stainless Steel 304 Box-Cut Frames Matter?

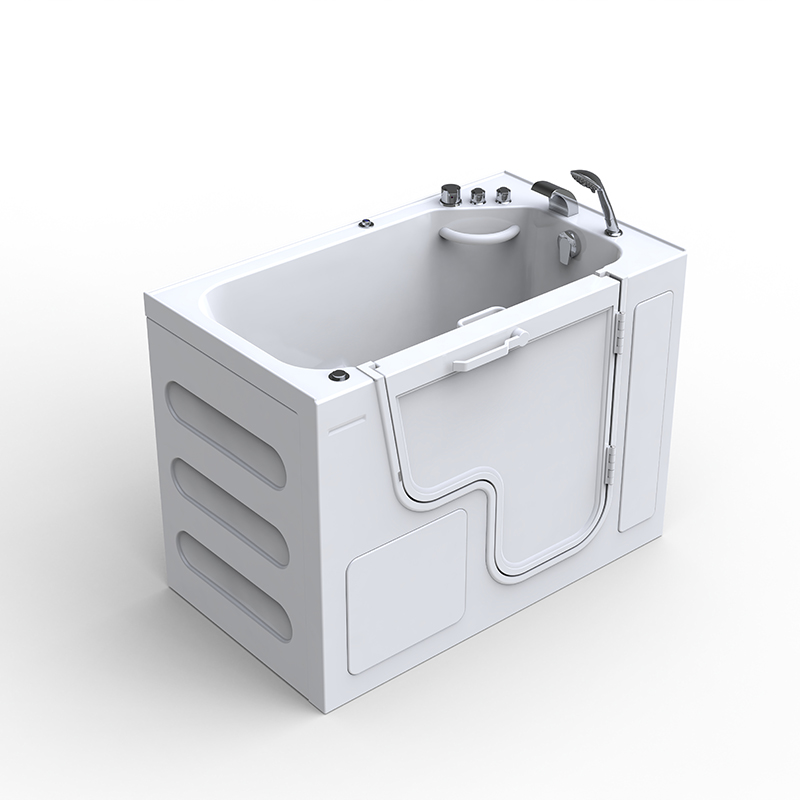

When choosing a high-quality walk-in bath, most people focus on comfort, safety features, or design. But beneath the surface of every durable, long-lasting bath lies something far more important — its frame. The frame is the foundation that supports the bath’s structure, ensuring it stays rigid, level, and secure for years of everyday use. At Odyssey Baths, we use stainless steel box-cut 304 frames in our walk-in baths and walk-in tubs, and for good reason. This premium engineering choice defines the strength, reliability, and lifespan of our products.

What Is a Stainless Steel Box-Cut 304 Frame?

A box-cut frame refers to a reinforced rectangular frame built from stainless steel tubing. This structure supports the bath from underneath, distributing weight evenly and maintaining rigidity even under pressure. Unlike cheaper open or tubular frames, a box-cut design prevents flexing, twisting, or sagging — all of which can occur over time in lower-quality baths.

The “304” in stainless steel 304 denotes a specific grade of steel, known for its high corrosion resistance and excellent tensile strength. This is the same high-grade steel used in the food, marine, and medical industries. In a walk-in bath or walk-in tub, that means superior performance and long-term protection against rust, moisture, and stress.

Why Stainless Steel 304 Is the Gold Standard

Stainless steel 304 is composed of around 18% chromium and 8% nickel. These elements create a strong, self-healing layer on the surface of the metal, protecting it from corrosion even in high-moisture environments like bathrooms.

Here’s why it’s the ideal choice for a walk-in bath manufacturer or walk-in tub factory:

Corrosion Resistance: Bathrooms are naturally humid spaces. Over time, cheaper metals can rust and weaken. 304 stainless steel resists rust, tarnish, and chemical damage — even from cleaning agents or bath salts.

Strength-to-Weight Ratio: Stainless steel 304 is incredibly strong yet relatively light, allowing us to build sturdy frames without unnecessary bulk.

Durability: It doesn’t warp, crack, or degrade over time. This ensures your walk-in bath supplier can confidently promise decades of reliability.

Hygienic Properties: The smooth, non-porous surface of 304 steel prevents bacteria buildup — vital in a product designed for accessibility and health-conscious users.

How the Frame Enhances Bath Strength and Stability

A walk-in bath must withstand more than just static weight — it supports dynamic loads every time someone enters, exits, or shifts position. The stainless steel box-cut frame serves as the internal skeleton that gives the bath its strength.

Here’s how it contributes:

Even Weight Distribution: The box structure spreads the user’s weight across multiple contact points, protecting the bath shell from stress and cracks.

Prevents Flexing: Acrylic or fibreglass baths can flex under pressure. A stainless steel 304 frame minimizes movement, ensuring the door seals perfectly every time.

Supports Components: Many walk-in tub manufacturers install pumps, jets, and plumbing systems directly onto the frame. The rigidity of stainless steel keeps these components stable, reducing maintenance issues.

Improves Longevity: The frame maintains its form for decades, keeping the bath level and eliminating long-term issues like uneven wear or water leakage.

Why Walk-In Bath Manufacturers Choose Box-Cut Frames

At Odyssey Baths, we’re proud to be a walk-in bath manufacturer that doesn’t cut corners. Our engineers design and assemble every walk-in bath frame using box-cut stainless steel 304 because it ensures superior quality control.

Compared to mild steel or wooden framing, stainless steel 304 offers:

Zero rot or corrosion — ideal for export and long-term installations.

Structural integrity under load, essential for deep soak baths and XL models.

Precision fitting with the bath mould for a seamless finish.

For a walk-in tub supplier or walk-in bath factory, this means fewer product failures, happier customers, and reduced after-sales maintenance.

Customisation and Quality Assurance

Every bath we produce at Odyssey Baths — from our compact Serenity range to our XL deep-soak models — begins with a custom-built stainless steel frame. Our team ensures each weld is smooth and secure, every corner perfectly squared, and each joint aligned for maximum stability.

This is especially important for mobility and disability-friendly baths, where user safety and confidence matter most. A sturdy, reliable frame supports not just the bath, but the trust our clients place in their walk-in bath supplier.

Environmental and Long-Term Value

Another advantage of stainless steel 304 is sustainability. It’s 100% recyclable, making it an environmentally responsible choice. Its longevity also means less waste over time — fewer replacements, less shipping, and lower environmental impact.

For homeowners, care facilities, or export partners, this translates into long-term value. The cost of a well-built walk-in tub may be higher initially, but a stainless steel 304 frame ensures that investment lasts decades.

The Foundation of Quality

Every walk-in bath factory knows the truth — a bath is only as strong as its frame. Stainless steel 304, crafted into a precision box-cut design, provides unmatched stability and safety. It’s what separates high-end walk-in bath manufacturers from those who use lighter, less durable materials.